ABOUT US

Who we are

Leading technical solutions for precision machinery parts, outstanding engineering technology, materials science, and surface treatment technology applications and innovations.

The innovative value we can provide you

Excellent innovative structural design and process innovation and optimization, such as: aluminum-magnesium-zinc alloy die-casting, copper-aluminum-iron profile extrusion, precision stamping, stretching, fine blanking, forging, two-color injection molding, metal-coated injection molding, aluminum-steel sand casting process innovation and application, involving various special surface treatment processes: such as conductivity, insulation, sealing, EMI, noise reduction, heat dissipation, PVD, heat treatment, sand blasting, shot blasting, powder coating, Teflon, ceramic oil, electrophoresis, oxidation and special raw materials performance improvement and other engineering technology innovations.

Competitive advantages in both large and small batches

We can meet the procurement needs of customers in different fields, such as small batch orders of 10-50 PCS. We flexibly and quickly respond to each customer's needs, such as: Engineering Verification Test (EVT), Design Verification Test (DVT), Production Verification Test, as well as large batches of 10,000-100,000 PCS. We provide excellent precision engineering solutions based on the diverse needs of our customers.

Excellent engineering solutions

Dozens of experienced engineers have more than 25 years of experience in precision parts manufacturing, with over 200 special characteristics of material science, engineering technology, surface treatment technology and application innovations, including leading precision molds, non-standard automation engineering integration engineering capabilities, and jointly participate in the research and development of new material innovation and special process applications with well-known professors from Sun Yat-sen University, Peking University, Shenzhen University and Xi'an Jiaotong University.

mission:

Focusing on the research and manufacturing of precision metal and plastic components, as well as the application and innovation of surface treatment technology, we have become a core strategic supplier for globally renowned brands.

vision:

Driven by technology, continuously innovating to create maximum value for customers, employees, shareholders, and society.

values:

Respect, professionalism, innovation, gratitude, and dedication.

Core concept:

Putting people first, team spirit, results oriented, and pursuing excellence.

150 +

Manufacturing TTeam

40 +

Research and Development Team

12000 ㎡

Factory Floor Area

1.6 Billion

Annual sales revenue in Renminbi

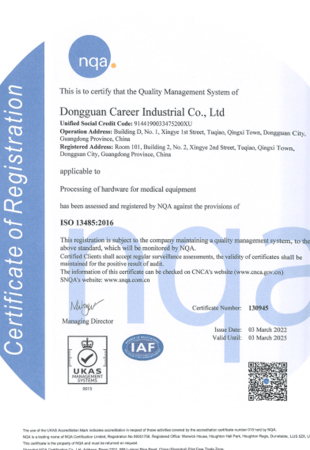

13485:16949

Quality Management System Certification

OUR ADVANTAGES

Materials Science Application Innovation

With nearly 30 years of experience in materials science application technology, Ruiyi provides optimal performance and appearance solutions for customers' new product development, covering both metallic and plastic materials, including various high-temperature resistant, insulating and conductive, carbon fiber, high-temperature resistant glass, isostatic graphite, silicon carbide, ceramics, titanium alloys, copper and aluminum profiles and pipes, magnesium alloys, high-temperature insulation, and polytetrafluoroethylene. Ruiyi also collaborates with renowned Chinese universities such as Shenzhen University, Peking University, Sun Yat-sen University, and Xi'an Jiaotong University to jointly develop and upgrade materials science applications.

Innovation in Surface Treatment Processes

Ruiyi provides customers with a variety of complex surface treatment color solutions and application innovations, such as: high temperature electrolytic oxidation resistant to 400-500 degrees Celsius, high temperature powder resistant to 10-200 degrees Celsius and above, high temperature electrophoresis resistant to 500-1000 degrees Celsius, spray painting, rubber paint, color electrophoresis, boron nitride, graphene, printing, laser engraving, heat treatment, I, ID, PVD, UV, metal and plastic overmolding, etc.

Innovation and Integration of Precision Manufacturing Processes

Kerui Amu has accumulated experience and technical talent in various precision parts processing and manufacturing, such as: magnesium-zinc-aluminum alloy die casting, copper-aluminum alloy profile extrusion, precision mold design, precision hardware stamping, precision stretching, continuous stamping, precision aluminum forging, CNC turning and milling, plastic injection molding, automation design and manufacturing, cost reduction and efficiency improvement process optimization and innovation, precision assembly, etc.